Recently, we made a special radial (centrifugal) fan simulation benchmark together with ZVVZ Machinery. This particular radial fan is quite difficult to simulate. It has a very complicated air flow including a low pressure ratio together with a high flow rate. This combination is very challenging for CFD. The following article is based on the public part of the report on the benchmark validation of a CFD simulation of a centrifugal fan using TCFD. This project was undertaken jointly by ZVVZ MACHINERY, a.s. in collaboration with CFDSUPPORT. The aim of the benchmark validation was to evaluate the TCFD, computational fluid dynamics (CFD) software and compare its results with the measurement data. The secondary aim of this project was to investigate the difference between steady-state and transient simulation results.

Keywords: CFD, VALIDATION, BENCHMARK, TCFD, SIMULATION, CENTRIFUGAL, RADIAL FAN, INCOMPRESSIBLE, AIR, TURBOMACHINERY, STEADY-STATE, TRANSIENT, LOW PRESSURE, AIR FLOW, AUTOMATION, SNAPPYHEXMESH

Benchmark Parameters Typical flow speed: 60 m/s Flow model: incompressible Rotation RPM: 1200 Mesh size: 2.8M cells Impeller diameter: 1.0 m Medium: air Reference pressure: 1 atm Typical Pressure Ratio: 1.03 Reference density: 1.2 kg/m3 Dynamic viscosity: 1.8 × 10-5 Pa⋅s CPU Time Steady: 6 core.hours/point CPU Time Trans.: 20 core.hours/point

Preprocessing

In this particular project, the mesh for the CFD simulation created from the surface model via an automated process (alternatively, the external mesh can be loaded directly). The original CAD model of the centrifugal fan was in the STEP file format. Original STEP files are usually too complex for comprehensive CFD simulations, so certain preprocessing CAD work is generally required. While the original CAD model for this project was simplified and cleaned using FreeCAD open-source software, any other standard CAD system can be used instead. The principle is always the same: the surface model has to be created; all the tiny, unimportant, and problematic model parts must be removed, and all the holes must be sealed up. This model is split reasonably into individual waterproof components. Then, the final simulation-ready model, the 3D surface in STL file format, has to be refined to a reasonable level. This preprocessing phase of the workflow is extremely important because it determines the simulation potential and limits the CFD results.

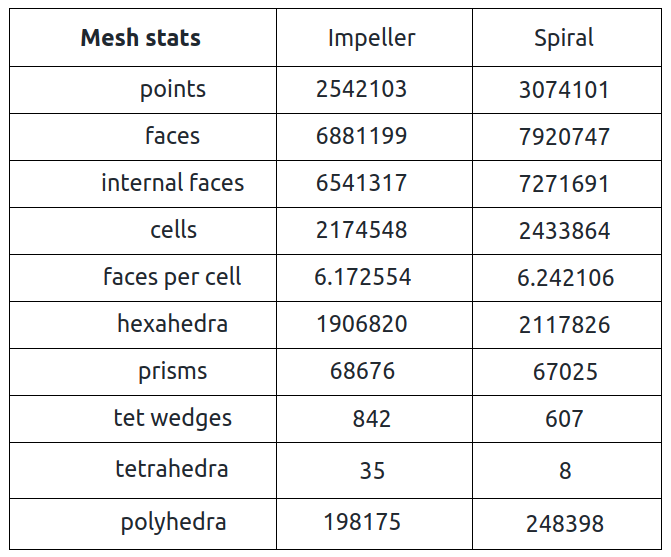

Mesh

The computational mesh was created in an automated workflow using snappyHexMesh. A cylindrical mesh was used for the initial background mesh of the fan impeller. The mesh refinement levels can be easily changed, to obtain the coarser or finer mesh to better handle the mesh size. Then, a boundary layer mesh of 5 inflation layers was created on the wall surfaces. Alternatively, an external mesh can be loaded.

Mesh Stats

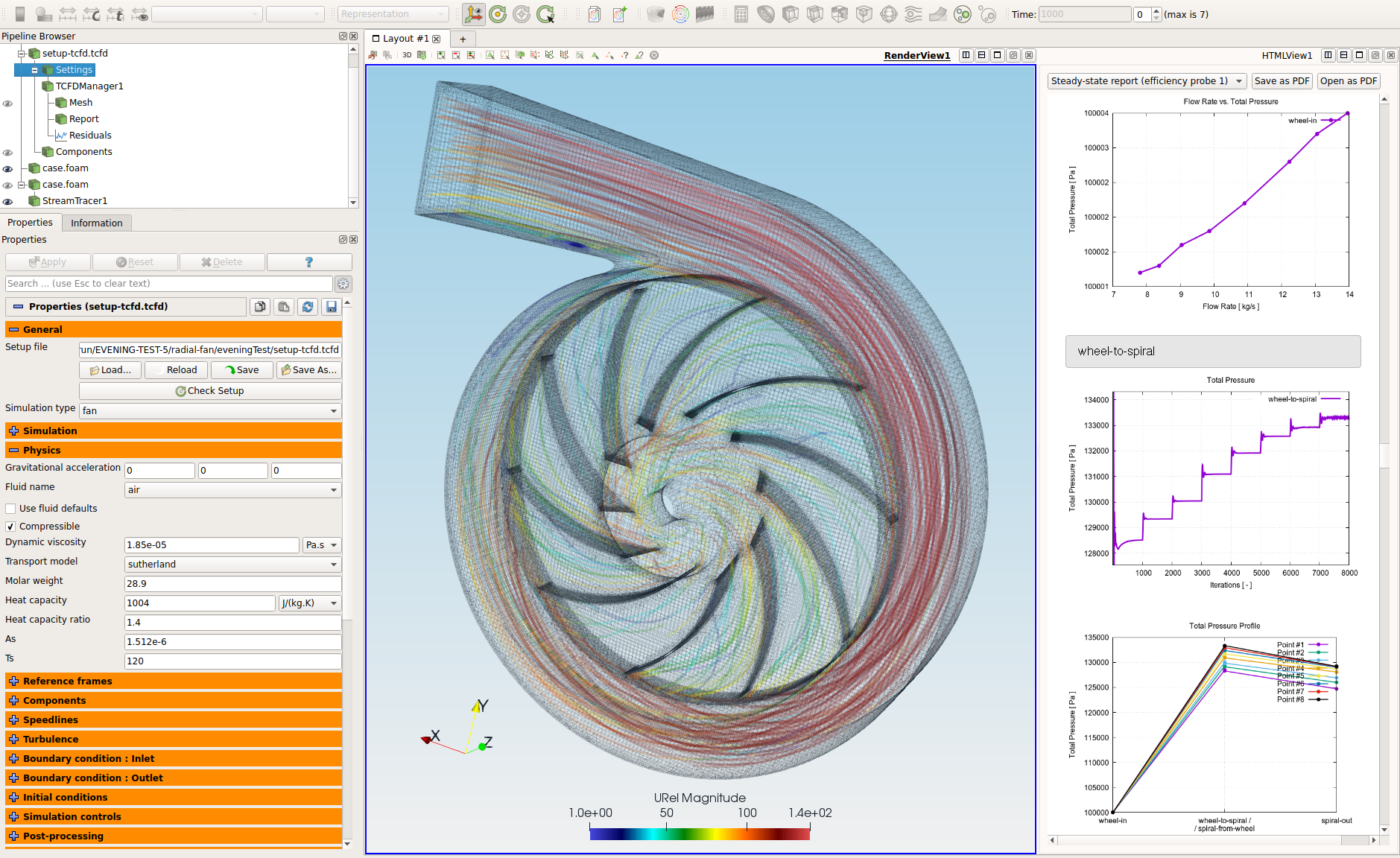

TCFD Case Setup

Machine type: fan Both Steady-state and Transient calculation Incompressible fluid flow RANS turbulence modeling with k-⍵ SST model Number of components: 2 Mesh Mesh size: 4.6M cells Inlet: Flow rate Outlet: Average static pressure Interface into Impeller: AMI Interface out of Impeller: Mixing Plane (10 planes)

The simulation was executed in the automated workflow in both steady-state and transient modes. The single speed-line of 11 points at 1200 RMP was simulated. TCFD is able to write the results down at any time during the simulation. The convergence of any quantity is monitored during the simulation. When any simulation point converges sufficiently, the simulation can move onto the next simulation point.

Post-processing

TCFD includes a built-in post-processing module which automatically evaluates the required quantities, such as efficiency, torque, flow rates, and forces and moments. All these quantities are evaluated throughout the simulation run, and all the important data is summarized in an HTML report, which can be updated anytime during the simulation for every run. Furthermore, visual postprocessing of the volume fields can be done with ParaView.

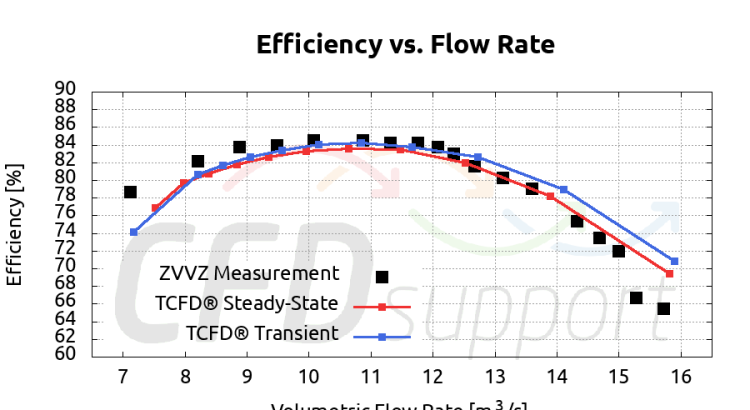

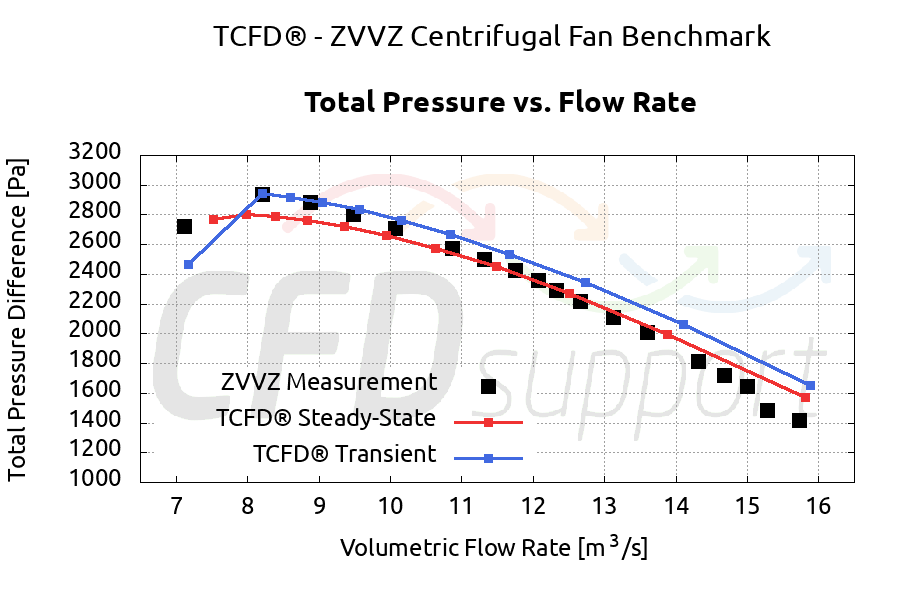

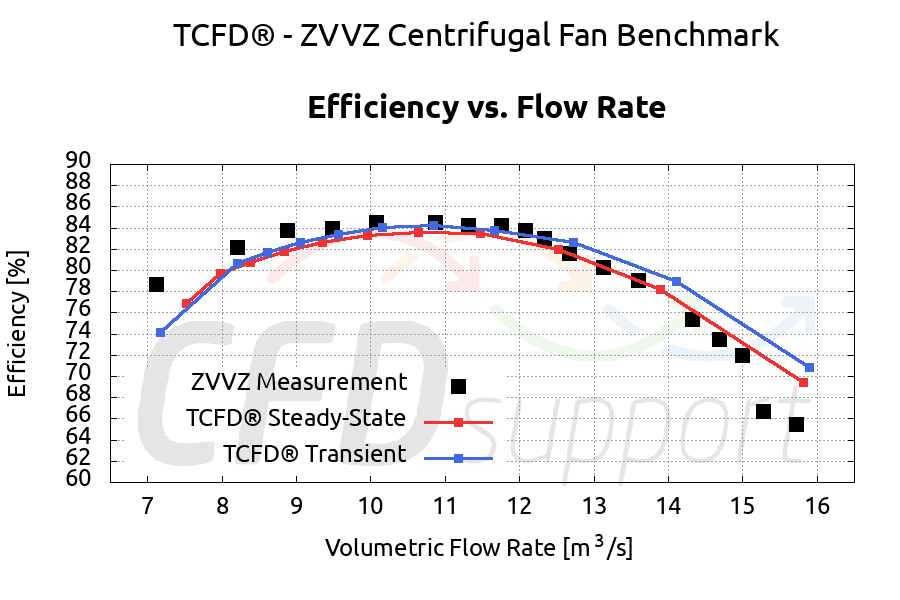

Results - Comparison with the Measurement Data

Conclusion

The complex CFD analysis of a centrifugal fan using TCFD provides very good agreement with the measurement data, as has been demonstrated. Overall, the transient simulation’s prediction is slightly closer to the measurement data than the steady-state simulation’s.

May you have any questions, feel free to contact us.

Best Regards,

Team CFD SUPPORT

PS: Please follow CFD SUPPORT on social networks: